In the process of assembling wood or board pieces together, joinery involves incorporating various types of joints. It is crucial to grasp the fundamental principles of joinery, regardless of whether you are constructing a simple coffee table or undertaking the construction of cabinets and cupboards on your own.

If you are new to DIY and woodworking, it may be difficult to determine the appropriate joint method for your project due to the wide range of options available. However, we have compiled a collection of the most commonly used joinery methods and their applications in furniture or other projects, which will help simplify the decision-making process for you.

Most basic joint:

A butt joint is a simple type of joint used in woodworking and welding.

We start by considering the most fundamental form of joinery, which is the humble butt joint. This type of joint is widely employed when connecting pieces together, particularly in simple DIY and woodworking endeavors. However, it should be noted that this joint is also comparatively weak.

To create a butt joint, one piece is overlapped with another, with one end butted against the other end. Pilot holes and screws are used to secure the overlapping section into the piece that is situated at the back.

Butt joints should be taken into account only for projects that will not exert any stress on the item being created or when extra reinforcement will be added.

A mitred butt or bevel joint involves cutting the two end pieces at an angle and connecting them. Such joints are commonly used in creating ornamental wooden boxes and projects that demand an enhanced decorative finishing touch.

To incorporate mitred joints into your projects, you must acquire a compound mitre saw, adjustable table saw, or router along with suitable router bits designed for cutting the angled edges.

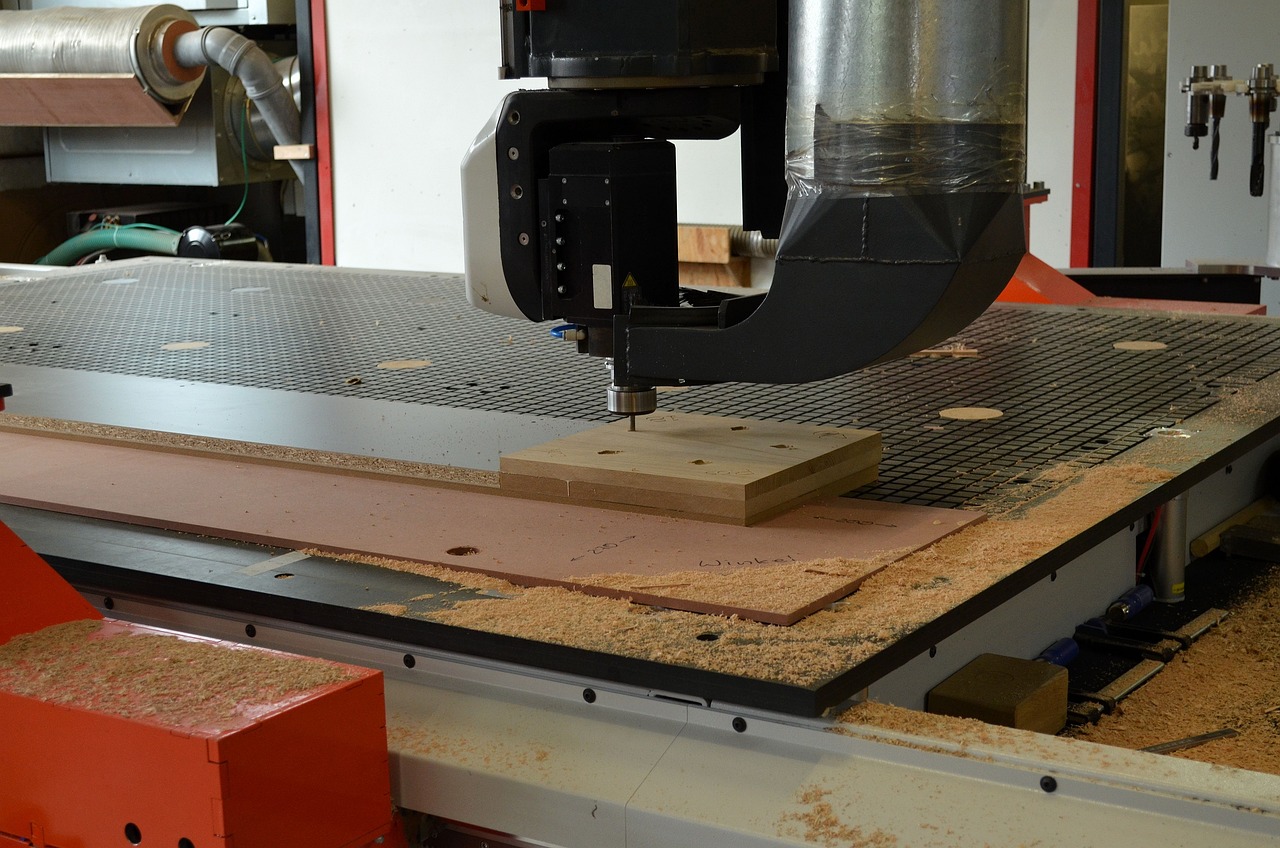

The techniques used in modern joinery

There are numerous recent and long-standing techniques for connecting wood, however, the tools necessary for creating these joints are not affordable for the typical DIY enthusiast. In this article, we explore various tools that not only improve the final look of projects but also facilitate their assembly process.

In South Africa, there are modern joinery tools like the biscuit joiner, pocket hole jig, and domino joiner that are wonderful for beginners in DIY projects. These tools enable the creation of furniture with sturdy joints, eliminating the need for complex joints and additional equipment. Here, we provide further details about these kinds of joinery machines.

A biscuit joiner is a tool used for joining two pieces of wood together. It works by cutting a slot, or “biscuit”, into each piece of wood, and then gluing them together.

Although not a new tool, the affordable Tork Craft Biscuit has been recently introduced to the South African market, providing beginner DIY enthusiasts with the same tool that woodworkers and carpenters have found highly effective over the years.

The domino joiner, a more advanced method of joinery, has replaced the biscuit joiner for experienced DIYers, cabinetmakers, and carpenters. However, due to its higher cost, most beginner DIYers cannot afford the domino joiner.

When considering the process, if you utilize a biscuit joiner or a domino joiner, these two tools possess similarities as they enable the registration or alignment of boards with a considerable level of precision.

The blade of a biscuit joiner is used to cut a slot of adjustable depth, shaped like a half-moon, which depends on the size of the biscuit being used. By cutting this slot into two neighboring pieces, it creates space to insert a biscuit. Together with wood glue, the biscuit expands and securely holds the two pieces in place.

Wood joining biscuits are available in three different sizes: 0, which is the smallest, 10, the medium size, and 20, the largest size. Depending on the project you are working on, you select the appropriate biscuit size. For decorative or non-stress-bearing joints, size 0 is ideal, while size 20 is suitable for joints that require the ability to withstand a significant amount of stress.

When would you use a biscuit joiner?

If you need to secure timber or wood-veneered board products together without having any screws visible, you can utilize a biscuit joiner. It is crucial to avoid visible screws, as they can only be concealed by screw caps or disguised with wood filler, neither of which provides a polished result.

If you frequently make tabletops or regularly glue several planks together, it is worth considering investing in a biscuit joiner, as it is a useful tool for such tasks.

Common joints:

A lap joint is a joint formed by overlapping two pieces of material and fastening them together.

A lap or half-lap joint involves cutting a rebate out of both sections to allow them to overlap. This joinery method is regarded as reasonably strong due to the added strength provided by wood glue.

To ensure that the joints fit together neatly, the stock is removed equally from both sections of the pieces to be joined.

Window frames’ muntins and mullions are often assembled using lap joints.

A joint called a cross-lap joint.

The cross-lap joint involves placing a piece of wood on top of another and connecting them. Like a butt joint, the lap joint is not known for its strength, but it is commonly used for overlapping or crossing two pieces.

A dado joint is a type of joint where a slot is cut across the grain of one piece of wood to fit into a corresponding slot in another piece of wood, creating a strong connection.

A dado refers to a slot that is cut horizontally across the grain of a wooden or board surface, enabling the insertion of another piece. This kind of joint is frequently employed when incorporating shelves into a project, like constructing a bookcase. By utilizing a dado, it becomes possible to join pieces together with wood glue instead of screws.

Dovetail joints, which are frequently employed for connecting drawers to create an aesthetically pleasing and skilled appearance, are highly robust. They are widely favored by carpenters and woodworkers, although they can be difficult for inexperienced individuals unless they possess the appropriate tools and jigs.

The optimal outcome is obtained when utilizing two distinct types of wood – one from the sides of the drawer and another for the drawer face – in the utilization of dovetail joints.

Kreg provides a variety of pre-cut wood plugs and a Kreg Plug Cutter to help conceal pocket holes in your projects, achieving an almost unnoticeable joint.

Other DIY Wood Joinery Techniques

Crosscut:

The term crosscut is used when a board is cut across the grain. This method, known as crosscutting, is commonly used to cut boards and is used to create butt and lap joints. On the other hand, cutting a board along the length with the grain is called a rip cut.

Using a logical thought process, rephrase the following text while keeping the same meaning intact. Avoid adding or removing any information. Joint of the Finger:

Another method used for connecting the sides of drawers and similar applications involves cutting the ends with identically-sized mortise and tenon pieces, which are then secured together using glue.

A butt joint made by gluing blocks together.

The text above explains that the basic butt joint can be enhanced by adding a triangle block on the inside for reinforcement. This is a common technique employed in furniture construction for items like table tops and chair seats, to ensure that the joints remain stable and unaffected by the stress resulting from usage.

The technique known as Mortise and Tenon involves joining two pieces of wood together by creating a hole (mortise) in one piece and a corresponding projection (tenon) in the other piece to fit into the mortise. This technique is commonly used in woodworking for its strength and durability.

When constructing finer furniture and cabinets, the technique of joining rails and stiles is commonly used. This involves cutting one board, known as the rail, to create a square peg or tenon. The other board, called the stile, is then cut with a square hole, or mortise, that matches the size of the tenon. A mortise and tenon joint is frequently used in the construction of furniture pieces, raised-panel doors, frames for cabinet faces, and other items. Although not of the highest quality, a biscuit joiner can be used to quickly create a mortise and tenon joint.

Rabbet, considering each step thoughtfully, and without adding or removing any information, rephrase the provided text while ensuring the same meaning.

One possible technique for creating a modified butt joint involves cutting a notch in either one or both ends of the boards that need to be joined. By doing so, the joint’s strength is enhanced as the surface contact area between the two pieces increases. Additionally, to further strengthen the joint, it is possible to use glue and clamps or incorporate screws.

One way to achieve a seamless fit between two boards is by using a simple rabbet. This involves cutting a notch in one of the boards to accommodate the entire thickness of the other board. Although the depth of the notch can vary, it is typically around half the thickness of the boards. Another option is to employ a double-rabbet join, where both boards are cut with corresponding notches to ensure a seamless union.

The process of making a rip cut involves thinking step by step and ensuring that no new information is added or removed while rephrasing the text.

Ripping refers to the act of cutting a board or plywood sheet along its length with the grain. The process can be done with either a table saw or a circular saw. The use of a table saw is considered the safest and simplest method for ripping boards. On the other hand, when ripping plywood, it is commonly done using a circular saw with a clamped board serving as a fence to ensure a straight cut.